When it comes to renovation and construction work, electrical power safety is of paramount importance to protect workers, the public, and property from potential hazards, damage and fatal accidents. With electrical, sometimes there are no second chances.

At Costo Construction Corp. we know how to identify potential hazards, incorporating them in our estimating, pre-construction, safety, scheduling and build processes.

It is imperative that property owners and contractors collaborate with local power utility companies to assess and address electrical safety considerations during construction or renovation projects. Two critical aspects of electrical power line safety in these contexts are the use of protective wrapping for overhead power lines as indicated above and power line locating underground or in concrete slabs as indicated below.

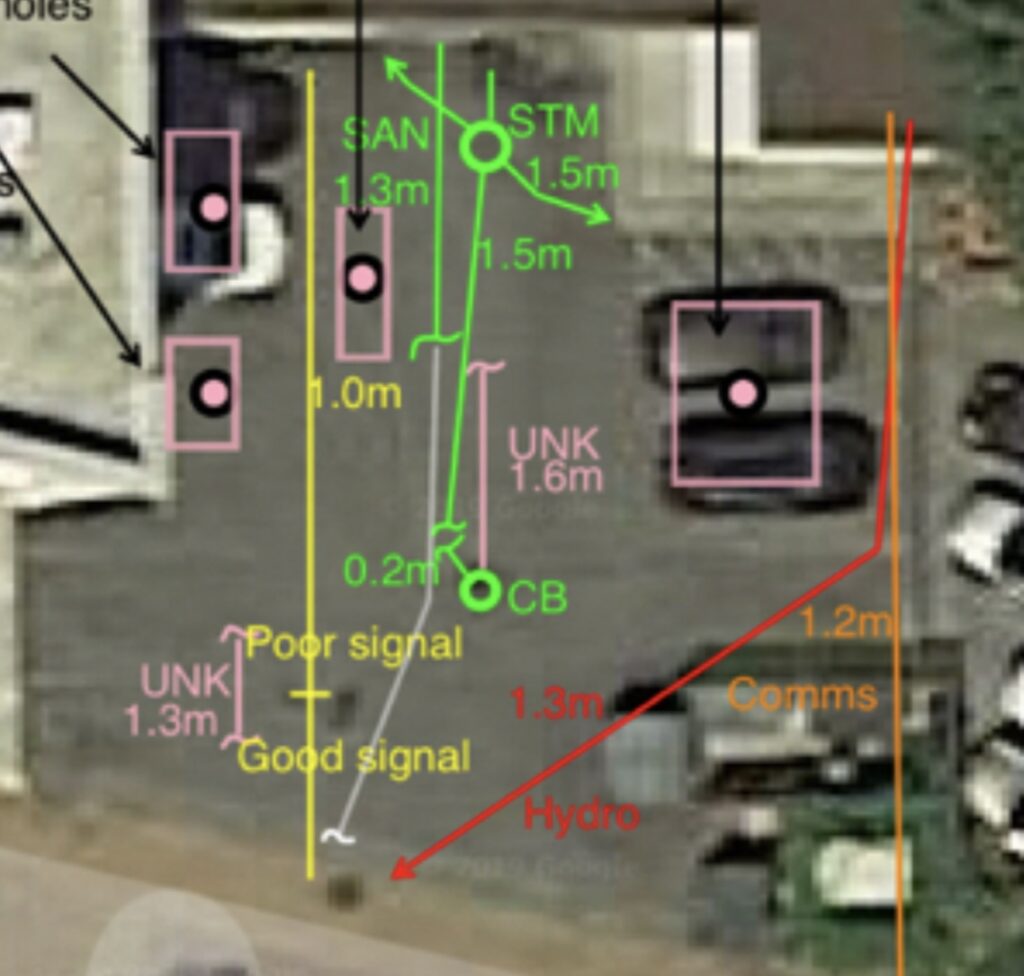

- Power Line Locating for Underground Utilities: Note above line marked in Red is underground high voltage electrical supply found at one of one of our sites when we employed ground penetrating radar (GPR) to locate various underground utilities and other items underground.

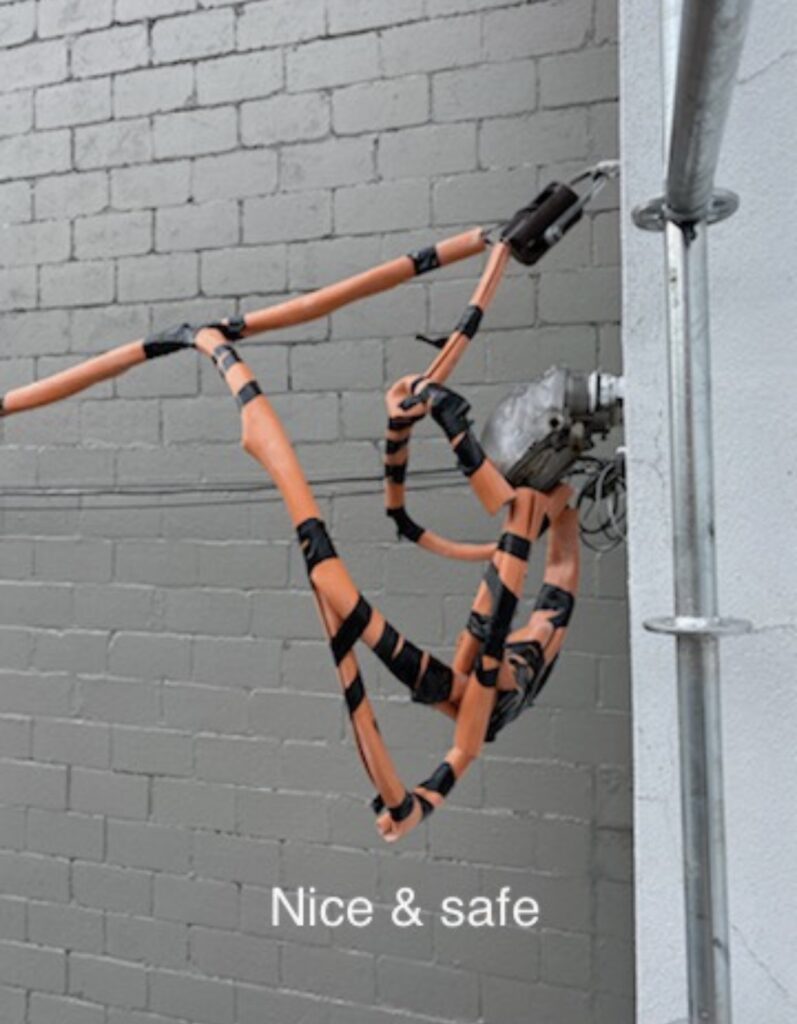

Before beginning any construction or excavation work, property owners and contractors must work with local utility companies and services to accurately locate underground power lines and utilities. This process typically involves contacting the local one-call center or utility locator service to request a utility locate. Here’s how this process works: a. Submitting a Locate Request: Prior to digging, property owners or contractors are responsible for submitting a “locate request” to the appropriate utility locator service. This request provides details about the planned excavation area and prompts utilities to mark the location of underground lines. b. Utility Marking: Upon receipt of the locate request, utility companies dispatch personnel to the site to mark the locations of underground power lines and other utilities using color-coded flags or paint. These markings help ensure that construction activities avoid damaging critical infrastructure. c. Safe Excavation Practices: Once the utilities are marked, contractors and workers must exercise caution and use non-destructive excavation methods, such as hand digging or hydro excavation, to verify the location of underground utilities and prevent accidental damage. - Power Line Protective Wrapping: Note the photo below shows utility service wrapped for worker protection at one of our sites.

For construction projects near overhead power lines, protective measures such as line wrapping may be necessary to minimize the risk of accidental contact and associated electrical hazards. Here’s an overview of power line protective wrapping: a. Temporary Insulation: In situations where construction activities bring workers and equipment in close proximity to overhead power lines, utility companies or their certified contractors may install temporary insulating sleeves or coverings on the lines to create a physical barrier and reduce the risk of accidental contact. b. Warning Markings: Additionally, warning signs and high-visibility tape may be installed near the protected power lines to alert workers to the presence of electrical hazards and reinforce the need for caution.

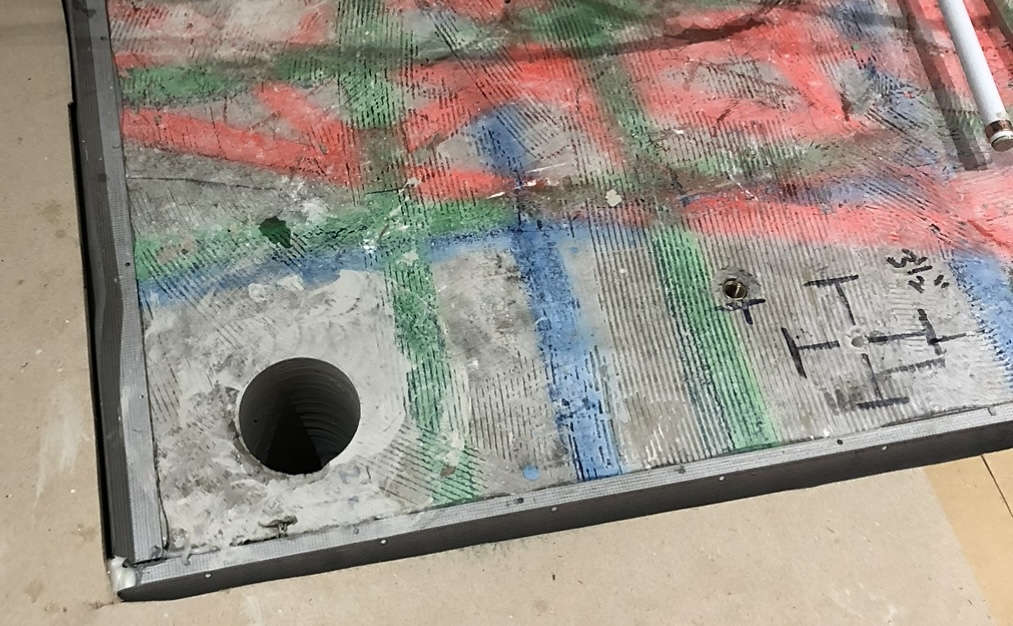

Concrete X-ray scanning, also known as concrete imaging or concrete scanning, is a non-destructive testing method used to visualize and locate embedded objects within concrete structures, such as rebar, electrical and mechanical conduits, HVAC ducting, and post-tension cables. This technology is widely employed in construction and renovation projects to ensure the safety, integrity, and structural stability of concrete elements. We routinely use this technology in our projects to identify the presence, depth and direction of rebar, PT / Post Tension Cables, HVAC ductwork and embedded electrical wiring. The following images show some of our work. In the first image, a technician marks out the location of top + bottom placed rebar in the slab as well as indicating the presence of, depth, direction of travel of electrical cabling in Red.

In the photo below, at a different coring location, we can clearly see that the core we made through the slab was done after the scanning was completed, with rebar and electrical marked. As a result, the core was made safely and away from these in-slab obstructions. Also, any cores are always only performed after a licensed Professional Structural Engineer has reviewed the X-ray report, visited site and approved of the coring location.

In conclusion, it is imperative that owners and contractors identify the locations of electrical lines whether it be in the air or in the ground anywhere around the proposed job site. This needs to be done for everyone’s safety. At Costo Construction, we take great pride in knowing the risks, and the required processes to follow when working around electrical. We manage the process from start to finish including providing valuable advice up front in the planning stage of a project to identify potential associated costs and the impact the safety work may have on schedule. If you would like more information about what we do and how we can help you prepare and plan for any type of commercial or residential renovation project, including electrical safety planning, simply get in touch with us! In the meantime, stay safe!